Giving shape to

clients’ needs

Producing authentic tastes

through our technology

and extensive know-how

Why Daiei Engineering?

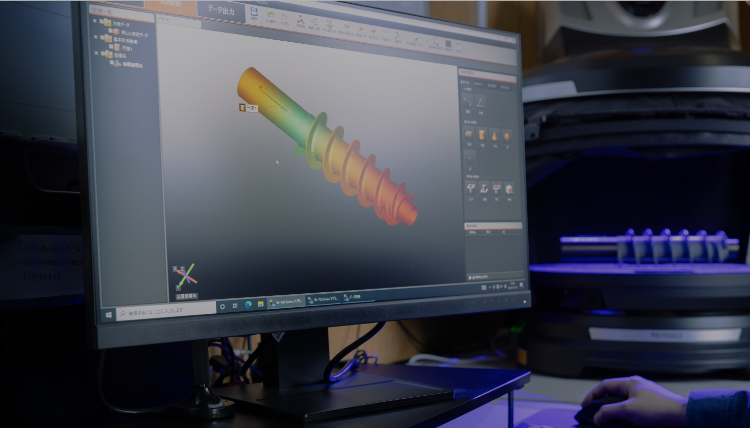

Precision product design

using the latest

measuring equipment

“Giving shape to clients’ needs” is one of the founding principles of Daiei Engineering, whereby we develop designs encapsulating the ideals our clients wish to convey through their passion and products. Gyoza pleats that appear handmade, distinctive samosa wrapping—we take pride in designing machines to enhance the key attributes of each product. Our precision designs, leveraging the latest 3-D measuring equipment, can help clients to achieve the authentic taste they are striving for.

Specialized parts machined and

manufactured in-house

Daiei Engineering’s plant boasts around 20 cutting, grinding and other machining tools, including 5-axis machining equipment, enabling us to manufacture intricately shaped parts in-house with great precision. Up to 70% of machine parts are produced in-house. Our designers communicate regularly with the production floor from the planning stage through to finalization, striving to ensure high quality craftsmanship without compromise. Furthermore, because we produce parts in-house, we can also provide comprehensive support after delivery.

Our engineers provide solid support,

from test-run through to post-delivery

Daiei Engineering has comprehensive support systems in place to assist the stable operation of client production lines. We dispatch our staff to clients worldwide upon request to provide speedy assistance. Our specialist engineers attend for initial product operation and maintenance briefings at time of delivery, and in the event of a breakdown due to worn parts or other issues—anywhere, anytime.

Commissioning process

Daiei Engineering consults with clients to fully understand the expected food size and production capacity, conducts simulations, and aligns itself with client needs to assist in realizing their requirements.

-

Pre-planning stage: specification briefing

Daiei Engineering determines the specifications for machines to manufacture in consideration of the expected food size, production capacity, and other requirements of the client. When determining machine specifications, we consult closely with clients regarding the characteristics of ingredients, preparation method, texture, shape, and other factors, to fully understand their passion and the ideals they wish to convey.

-

Simulation prior to final planning

We conduct simulations using a sample machine according to the specifications determined through consultation, to confirm precise machine specifications. In the unlikely event that the food produced does not meet client expectations, we prepare a new blueprint to make improvements, manufacture new parts, and continue verification tests. We repeat simulations until machines can produce the food that the client requires.

-

Final planning & design preparation

Our engineers prepare machine blueprints based on specifications following simulations.

-

Confirmation of detailed specifications

We confirm the fine details to ensure blueprints are in line with client requirements.

-

Manufacturing

We arrange for materials and machining according to the blueprints, and determine the manufacturing schedule based on the delivery date. Engineers process and inspect the required parts, which are assembled by master engineers. At this stage, engineers manually perform intricate adjustments that are difficult to handle mechanically.

-

Test-run, adjustment & pre-delivery inspection

When machines are ready, we conduct an on-site test-run and make adjustments with the client present.

-

Briefing at time of delivery

We provide guidance on machine operation and maintenance at the time of delivery.

Custom-made machines

If you require machines that are not in our lineup, please let us know. Following consultations, we will investigate detailed specifications based on your needs, such as:

- Food shape

- Food dimensions

- Food weight

- Materials

- Shaping method

- Machine dimensions

- Electricity consumption

- Maintainability

Clients considering

custom-made machines

Following discussions, we will investigate the marketability of your required food processing machine before undertaking its development. Please be aware that, in the unlikely event of an extremely low sales forecast, we may decline the request.

Frequently asked questions

Please find the answers to our most frequently asked questions below. Do not hesitate to contact us if you have questions regarding other matters.

- QDoes Daiei Engineering sell secondhand food machines?

- AAlthough we do not sell secondhand equipment, if you are seeking more cost-effective options, or products you have become accustomed to using, please contact us to discuss the possibilities.

- QHow long does machine delivery usually take?

- AThe time taken from ordering through to shipment varies according to machine specifications. We do our utmost to meet client expectations, so please advise us in advance of your desired delivery date.

- QDoes Daiei Engineering stock spare parts and consumables?

- AWe stock bearings, gaskets, and other spare parts and consumables that are essential for the operation of machines. Please contact us whenever the need to replace old parts arises.